NORREQ supplies tailor-made, high-quality modular building solutions

If you would like a presentation of our modular building solutions, contact us!

NORREQ represents Modulbygg from recognized and certified suppliers who have been active in modular construction in the international market since the mid-90s. We deliver total solutions for design, construction, and assembly.

The production of modules takes place on large and partially automated production lines. Based on many years of experience in the construction of, among other things, public buildings, apartment blocks, and hospitals, our suppliers meet all requirements for quality and implementation.

NORREQ can therefore offer innovative and modern module systems to the Norwegian market based on prefabricated modules of very high quality.

Some of the advantages of using modular technology compared to traditional construction techniques

- 30% less time to complete the project

- 30% improvement in thermal insulation coefficients

- Lower energy consumption

- Coordination of design and construction work is carried out by professionals from the manufacturer

- Expansion, upgrading, and modernization of existing facilities

- Prefabrication takes place indoors and under controlled conditions

- The production facility and the scope of work carried out on the construction site were reduced to a minimum

Some of the special areas for Modulbygg

- Hospital

- Terraced house

- Apartment blocks

- Laboratories

- Pharmacy

- Police stations

- Fire stations

- Military buildings

- Datacenter

- Public buildings

- Schools

- Kindergartens

- Offices

- Hotels

In projects where the space is occupied by two or more modules, the prefabricated modules are mostly finished, and the rooms are finished after assembly on the site (mainly for communication lines, operating rooms, classrooms and conference rooms, cages, stairs, etc.)

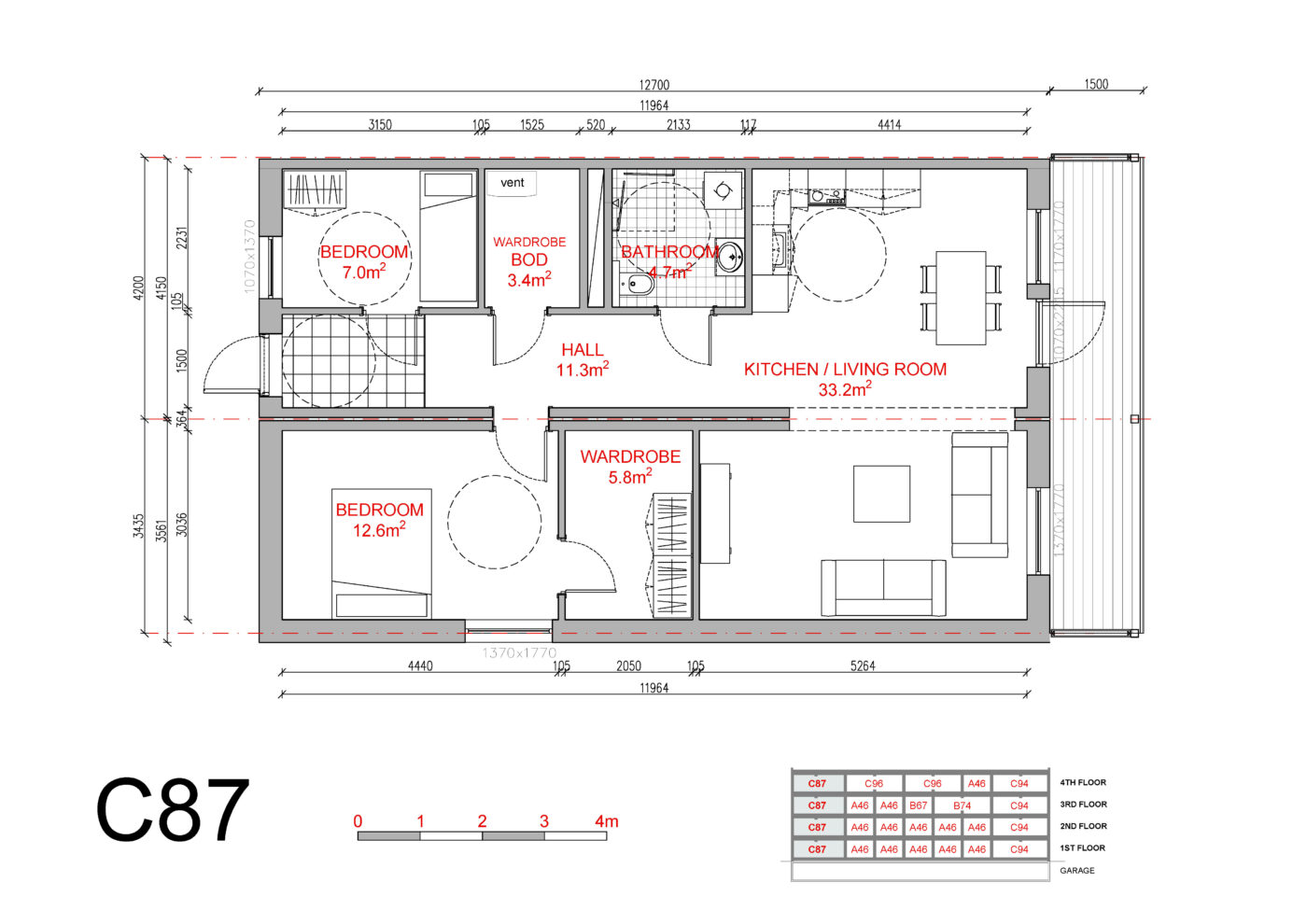

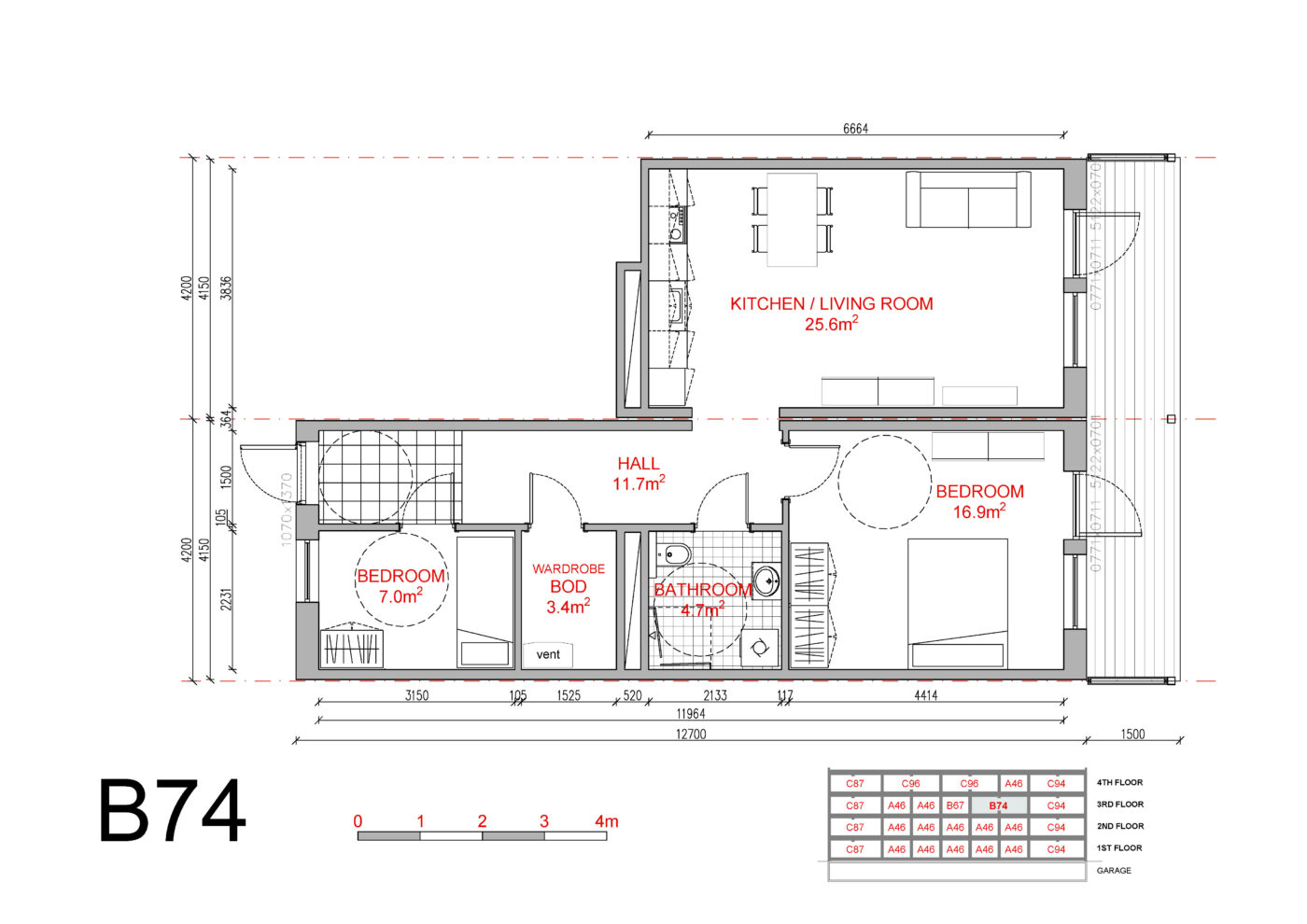

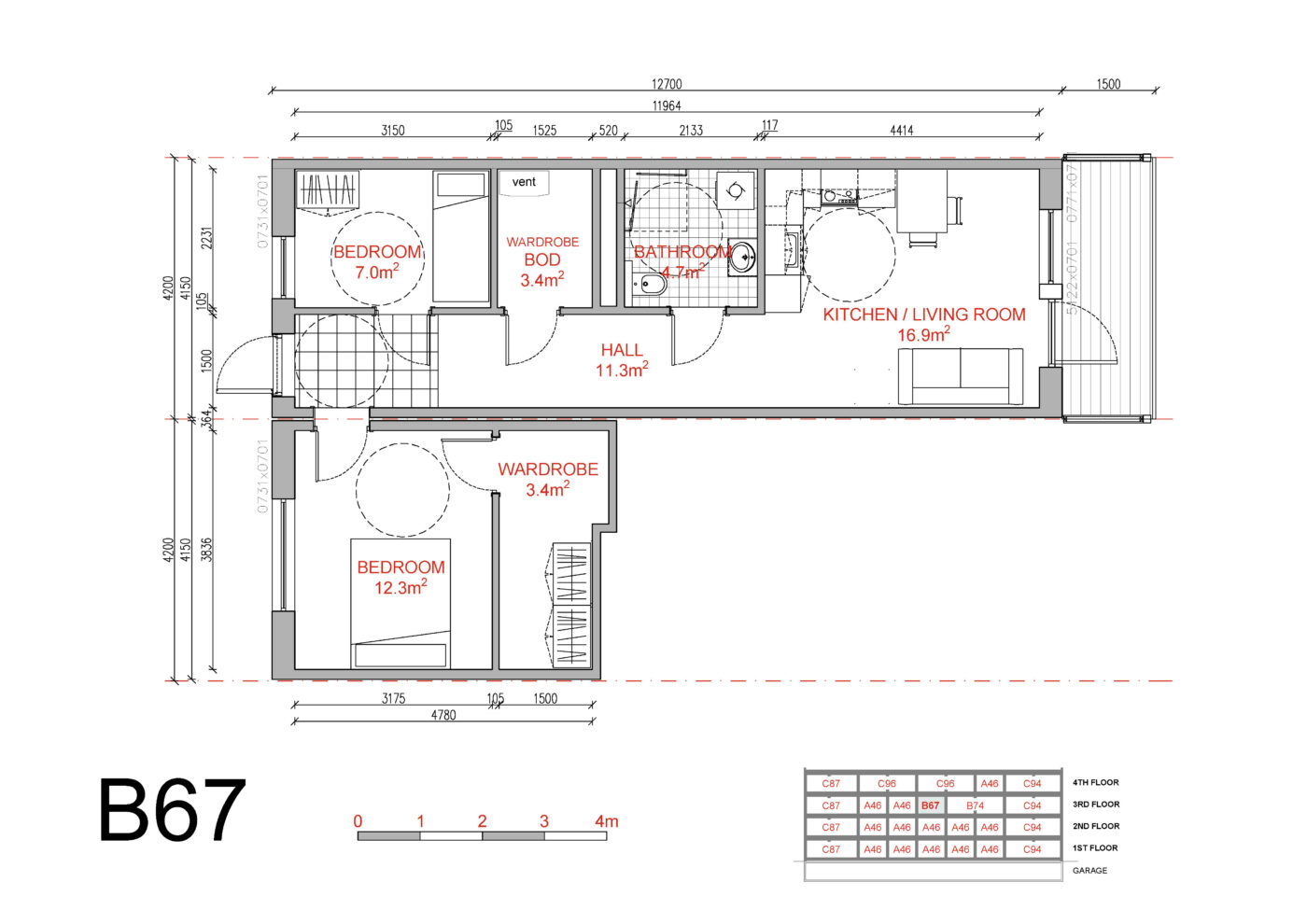

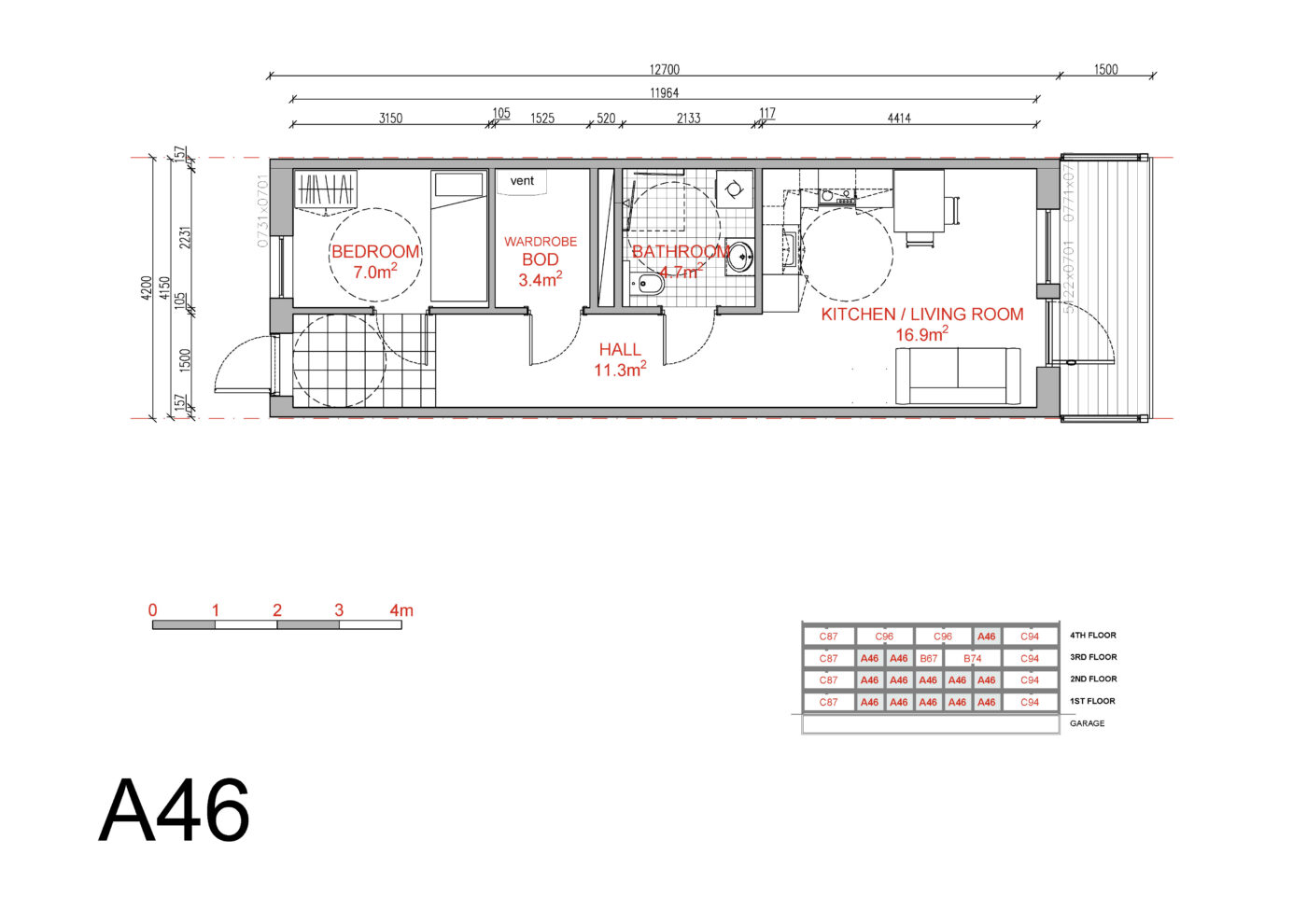

All modular systems supplied by NORREQ meet all Norwegian building requirements, where at each stage of both design and implementation it is possible to adapt the building to other customers’ requirements and adapt the system to other construction applications. The modules are separate, prefabricated elements that carry the payload, made of profiles

The payload of modules may vary depending on the type of extension on prepared foundations, prepared reinforced concrete, steel or combined substructure, a lower modular structure (in the case of multi-story structures) existing building structure (in the case of the superstructure of existing buildings).

The modules can be used as independent buildings, additions to existing buildings, or superstructures on existing buildings.

Depending on needs, the modular system enables construction on up to 10 floors.

- Modules delivered to the construction site can be completed with full technical equipment and all installations – according to the customer’s requirements.

- Modules prepared in that way for construction are only joined together and completed and adapted to already existing infrastructure. In the case of projects where the room is placed in a single module – the premises are prepared turnkey (unless other conditions prevent it, for example, guidelines for installation equipment).

- For projects where some rooms cover an area of two or more modules, prefabricated modules are essentially finished, but the rooms are finally finished after installation on site (this applies to all communication routes, operating rooms, training centers, stairs, etc.).

- Thanks to its flexible design, a modular system can be an extension of the building in any configuration and at any level – the system allows both to be extended at ground level, as well as to be developed at any level (as a self-supporting structure independently supported on posts or partially based on the existing building) and superstructure on the roof (it is a particularly attractive solution in case of problems with difficult machine room installation).

- The mobility and versatility of that solution make it possible to use the modular system also in places with very limited access, for example, a patio or the roof of the building.

- With an experienced installation staff, even complex implementation is done quickly and efficiently.

A standard module delivery normally includes the following

- General lighting

- Electrical installation

- Administrative night lighting

- Plumbing – drainage systems, including fire protection and drains

- Ventilation systems

- Heating systems, radiators

- Ventilation and air conditioning units with automation

- Supply panels for air handling units

- Door and window joinery

- Fire-fighting equipment (e.g. fire dampers, etc.)

- Evacuation DC (direct current) installations, UPS

For modules for hospitals, the following is included

- Medical equipment, operating room

- Furnishing the hospital rooms with mobile equipment

- Furniture, hygienic wall panels – made of stainless steel

- Galvanized or glass / laminate HPL according to specification

- Installations of germicidal lamps

- A signaling system, SAP (fire protection) installations

- Systems for air recirculation in the operating room

- Equipment and systems for medical gases

- Additional air conditioning, cooling systems, and additional heating systems

- Systems for automatic air pressure control

- Radiological and electromagnetic protection systems for selected rooms

- Other – according to the customer’s requirements

NORREQ offers turnkey solutions and can also deliver modules fully furnished. Modular construction also provides the opportunity for new financing solutions. Get in touch for a meeting or a presentation of our modular building solutions.

Erlend Strømnes

CEO

Jonas Brodie Tobiassen

Operational Manager